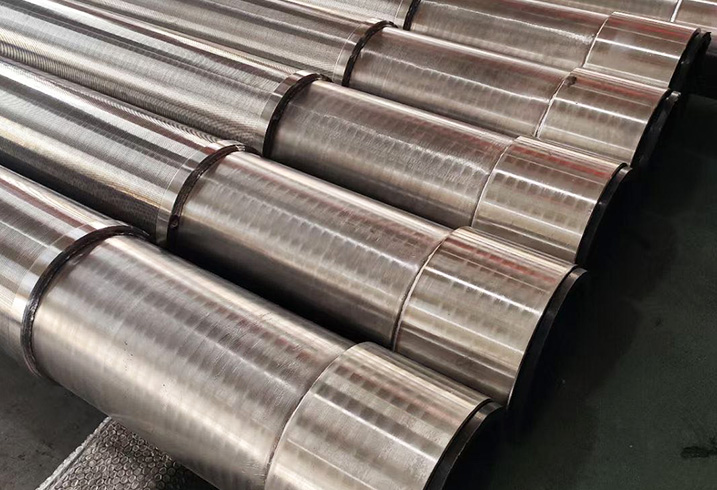

The gravel pack screen pipe consists of perforated pipe, outer jacket ,end ring and centralizer. Key-stone or house shape wires are simultaneously wrapped and welded to form uniform slots. The jacket is then placed over perforated pipe and welded to each end.

Usually used in the deep wells, such as 1200 meters wells.

V-shaped wire creates keystone geometry and self-cleaning performances for lower possibility of clogging.

External forces are directly transferred to base pipe.

Many ribs are designed for collapse resistance.

Wire wrapped screens produces ten times of open area as the size of slotted liners. This significantly improves well life and filtration capacity.

Gravel packing screen pipe has great sand controlling capacity,and so far it is a advanced sand controlling technology

They consists of two screens or multi-layer screen and the stuffing between the screens.

Gravel packing screen pipe has great sand controlling capacity,and so far it is a advanced sand controlling technology under the well. Meanwhile,our company can offer a whole set of service,such as the related process,the solution of the related technology and so on.

We design to allow slurry to bypass sections that have bridged prematurely or become obstructed during gravel-pack operations.

With multiple apertures located along the packing tubes in each screen, flow is redirected through the shunt tube system and the shunted screens more uniformly distribute the gravel or the slurry across the well bore.

Enhanced Low Profile and Premium Gravel Packing Screens — These screens can be used in gravel-packed and non-gravel packed wells.

They incorporate a strong inner wire wrap layer made from round wire and a keystone-shaped outer wire wrap layer.

Prepacked Screens/Gravel packing screen pipe — When gravel packing is not feasible, prepacked screens provide built-in sand control.

They incorporate a keystone-shaped wire for the inner and outer wire wraps.

Single with bubble bag and then in wooden case(fumigation certificate) or directly into container

| Screen Information | |

| Material | stainless steel, carbon steel |

| Hole of based pipe | 16mm-30mm as your require |

| Support Rods | 2.2*3.5mm, 3*5mm, 3.2*6mm, 4*7mm |

| Wire Size | 2.2*3.5mm, 3*5mm, 3.2*6mm, 4*7mm |

| End Connection | Male/Female thread, Flange, Welded Ring |

| Certification | ISO, CE, SGS |