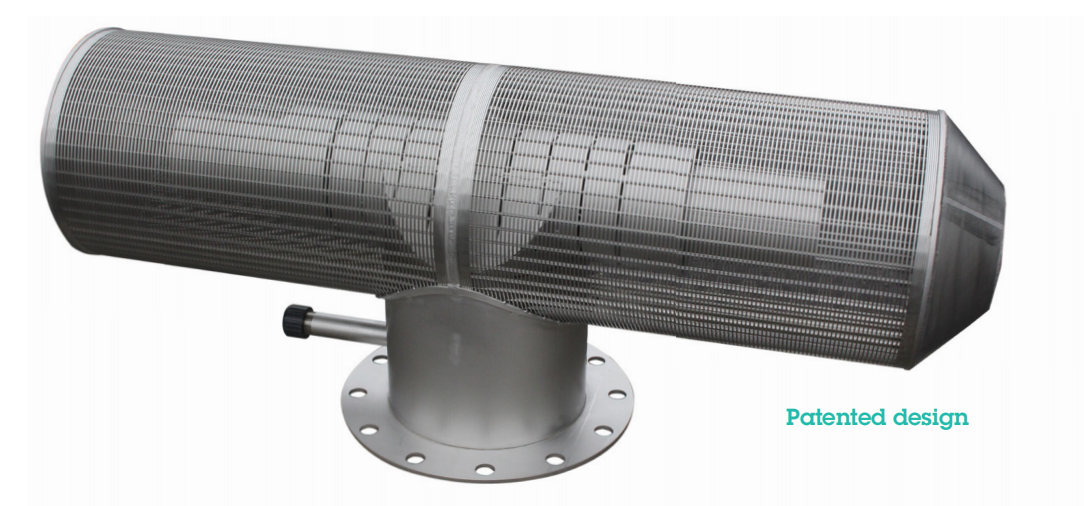

Stainless steel 316L Passive water intake screens can withdraw water uninterruptedly from lakes, rivers and oceans at a low, uniform velocity.

Sino can design the intake screens according to customers’ requirements.

Various stainless steel alloys can be used to construct intake screens for fresh and sea water applications.

The intake screens cost less to install and operate and require less maintenance.

|

Wedge wire

|

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70

Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00 |

Diameter

|

from 25mm to 1200mm.

|

|

Support rod

|

Width(mm): 2.30 3.00 3.30 3.70

Height(mm): 2.70 3.60 4.70 5.60 6.30 Round: From 2.50mm to 6.0mm |

End connection

|

Plain beveled ends, flanged or threaded couplings

|

|

Slot size

|

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request.

|

Certification

|

ISO9001

|

|

Material

|

Galvanized low carton (LCG), stainless steel (304,316 etc.)

|

Length

|

up to 6m

|

Structural Principle:

Stainless steel 316L Passive water intake screens is a key equipment widely used in seawater treatment, which can effectively filter seawater and protect subsequent processing equipment from particles and organisms.

* In seawater desalination plants, passive intake screens are used to filter impurities and particles in seawater, to ensure a

smooth subsequent desalination process.

* In marine engineering construction, passive intake screens are widely used in seawater cooling systems and seawater extraction systems. The stable structural design protects engineering facilities from damage and ensures the stable operation of the systems for a long time.

* In the field of marine ecological conservation, passive intake screens are used to reduce the capture and impact on marine organisms. Its micro-hole design minimizes interference with marine organisms, and protects the integrity and stability of marine ecosystems.